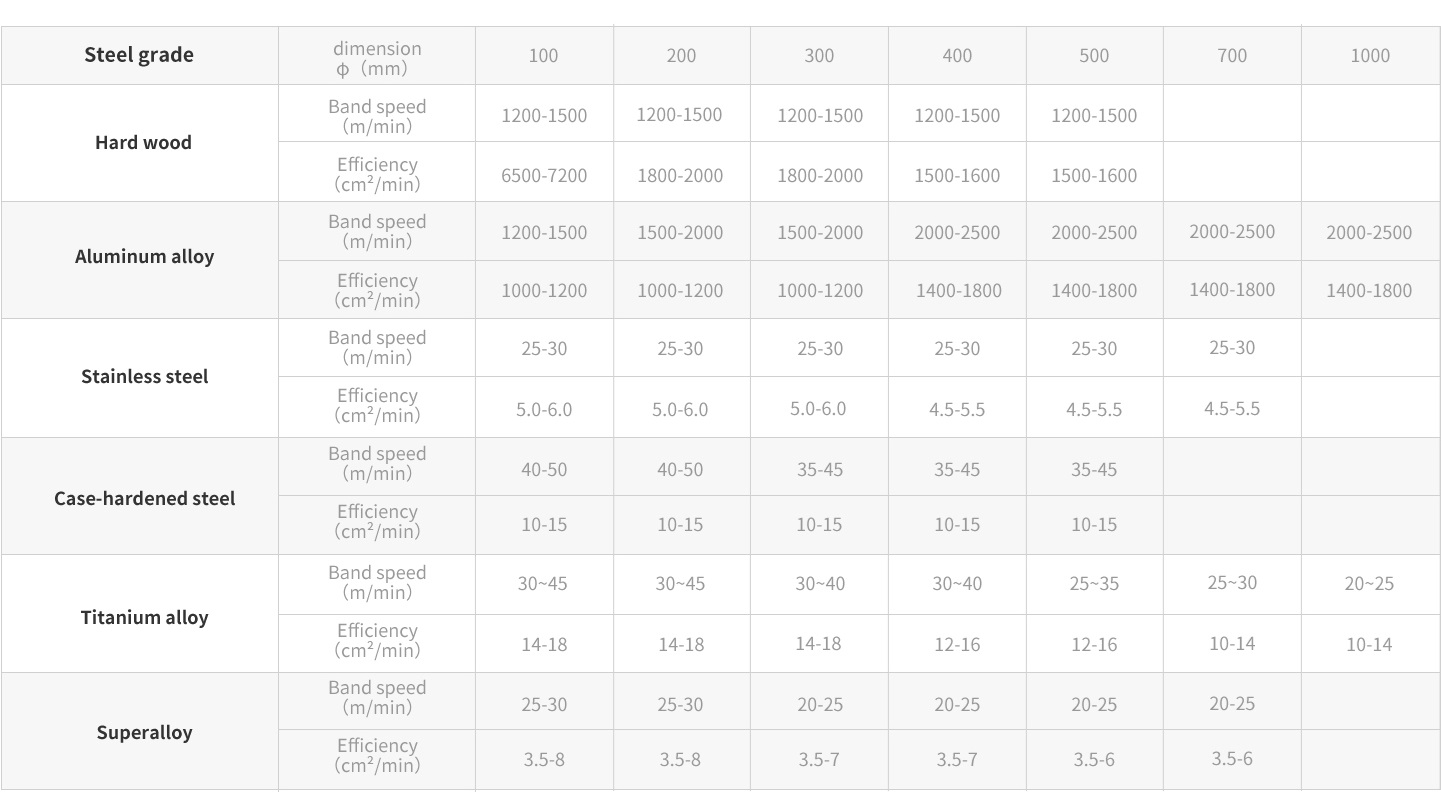

BEFORE BREAK-IN

Tooth tips are very sharp and sometimes with some small burs from manufacturing.

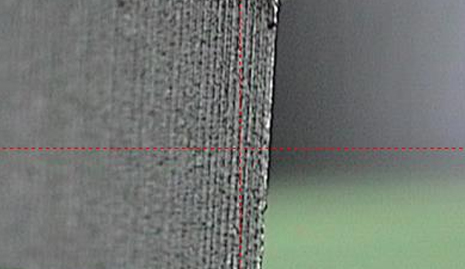

AFTER PROPER BREAK-IN

Proper break-in makes blades gain a good tooth tip with small round cutting edge,which is beneficial for prolonging blade life.

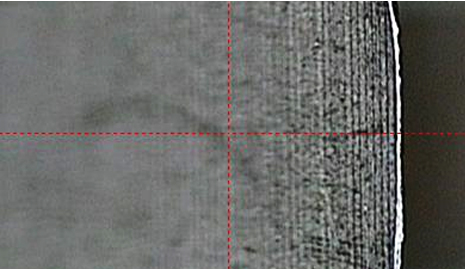

AFTER IMPROPER BREAK-IN

lmproper break-in results in disastrous chipping on tooth tips,which shortens blade life greatly.

For bi-metal bandsaw blade

√Use the recommended band speed for the material you want to cut.

√Reduce the feed rate with 30-40%.

√Run the blade for 30-60 min and slightl yincrease the feed with every cut.

√Set band speed and feed rate as normal.

For carbide bandsaw blade

√For the 1st cut,set feed and band speed parameters as for a bimetal.

√For the second cut increase band speed,while avoiding vibration.

√Then increase feed to match band speed while avoiding vibration.

√Repeat second cut till you have reached normal parameter values for a carbide blade.

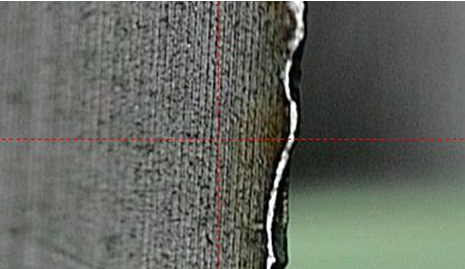

For bi-metal bandsaw blade

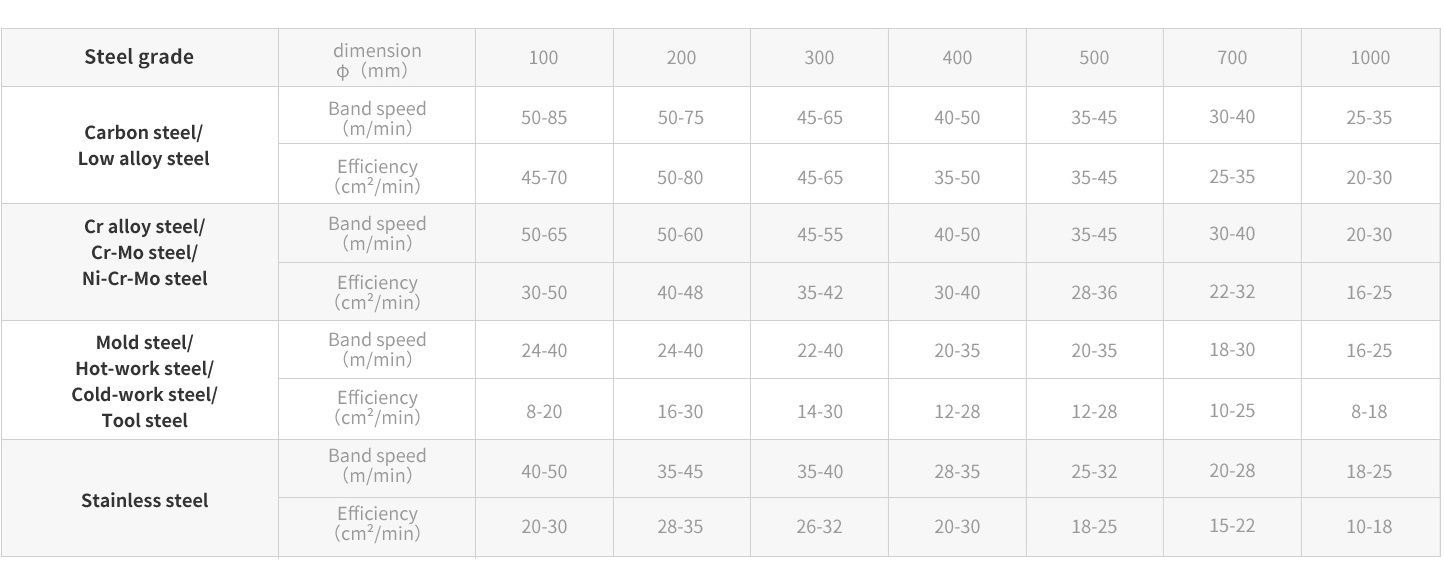

The chart is only for materials with hardnes of 20HRc or 225HB.When hardness ~30HRc or 283HB,slow the speed to 70% of the recommended in the char.When hardness~35HRc or 330HB,slow the speed to 60% of the recommended in the chart.Bi-metal is not suggestible for workpiece with hardness higher than 40HRc .

Actually,bandsawing parameter is strongly afected by external factors like machine condition,materials,fuid,etc.So your experience is very important.

For carbide bandsaw blade